Stellantis has recently announced a groundbreaking agreement with Texas-based Zeta Energy to collaborate on the development of lithium-sulfur batteries. These innovative batteries have the potential to significantly reduce costs and pack weight, while also improving charging speed.

According to Stellantis and Zeta Energy, lithium-sulfur chemistry can provide comparable volumetric energy density to current lithium-ion battery cells, but at a price that is less than half the cost per kilowatt-hour. By utilizing sulfur, which is abundant and inexpensive, and incorporating unrefined sulfur from other industries and waste materials, these batteries aim to minimize costs and carbon dioxide emissions.

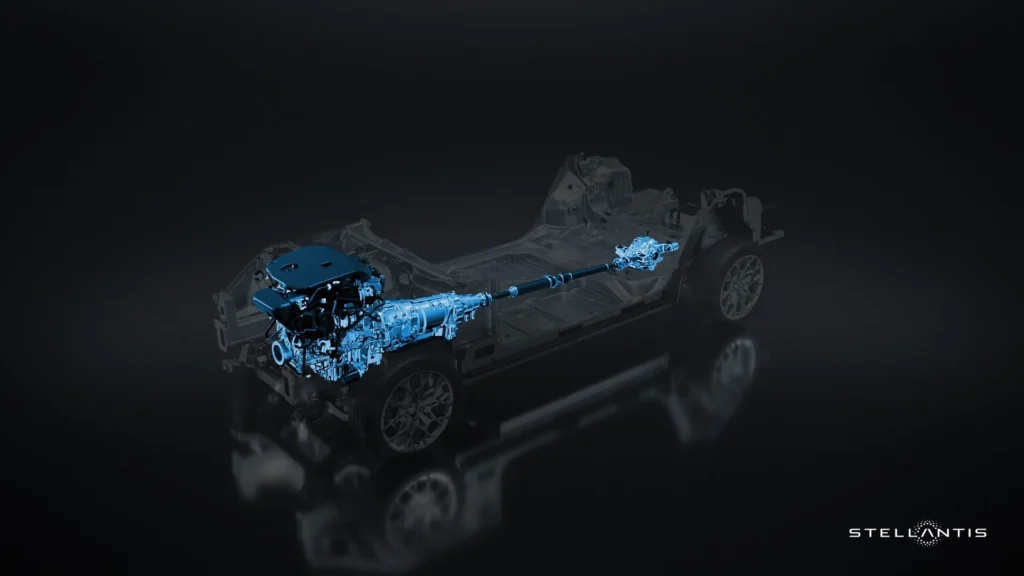

STLA Large platform

The lithium-sulfur technology also has the potential to increase fast-charging speeds by up to 50% and significantly reduce the weight of battery packs while maintaining the same usable capacity as lithium-ion packs.

This collaboration is focused on pre-production development work with the goal of potential commercialization by 2030. Stellantis plans to leverage existing battery factories and aims to keep the battery materials supply chain localized in either Europe or North America.

Stellantis STLA Medium platform

Stellantis had previously partnered with Lyten in 2023 to work on lithium-sulfur battery technology and had made investments in the California-based startup through Stellantis Ventures. The automaker clarified that the collaboration with Zeta Energy complements its partnership with Lyten.

Over the years, lithium-sulfur batteries have been seen as a promising technology to enhance range without increasing weight or production costs. While there have been advancements in the past decade that have overcome key obstacles, challenges such as mass production and cell longevity remain. It will be intriguing to observe how Stellantis tackles these issues in the coming years.