Hyundai and Kia Innovate Battery Pack Integration in Vehicle Structural Components

Hyundai and Kia are pioneering a new approach in the automotive industry by combining battery-pack cases with vehicle structural components to enhance packaging efficiency.

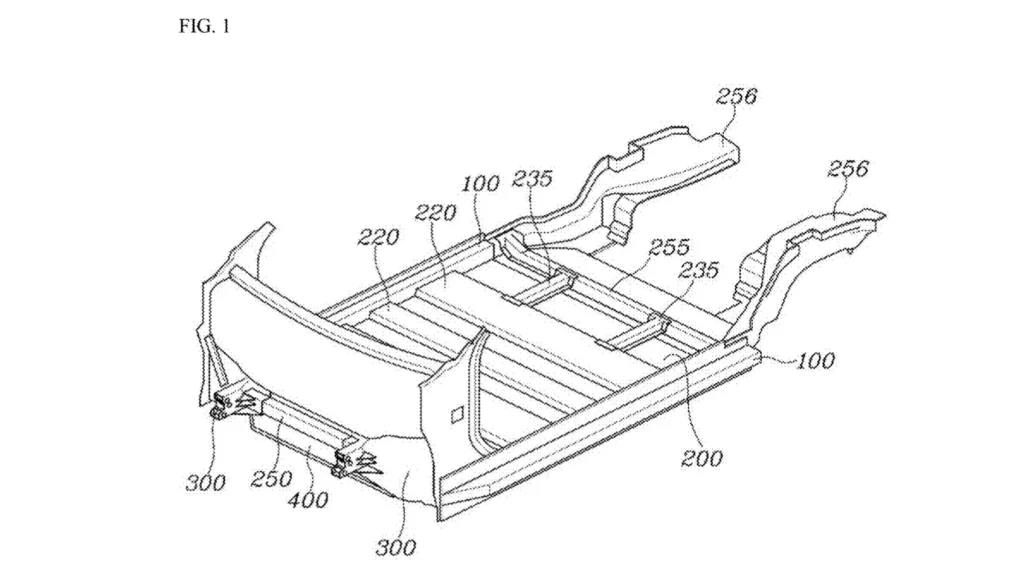

In a recent patent filing published by the United States Patent and Trademark Office (USPTO), Hyundai and Kia propose utilizing a vehicle’s floor as the upper panel of a battery pack case. This innovative design maximizes available space, allowing for the fitting of more modules according to the automakers.

This integration of the battery pack with the vehicle’s structure involves attaching major components such as side sills and cross members to the floor panel, which also serves as the upper battery case panel. The filing suggests a potential use of extrusion fabrication method to blend some cross members with the floor panel.

The battery modules would be positioned underneath the floor, utilizing voids not occupied by crossmembers. Front and rear barriers would protect the pack and seamlessly integrate with the side sills, as outlined in the filing.

Hyundai and Kia’s innovative approach aligns with the industry trend of exploring structural battery packs. Tesla introduced its own design at the 2020 Battery Day, emphasizing the benefits of a structural battery in reducing mass and increasing range. Startup Canoo integrated structural batteries into its skateboard platform while maintaining modules for weight reduction.

Chinese startup Neta Auto and battery supplier CATL are also pushing boundaries by integrating cells directly with a vehicle’s chassis, building on CATL’s cell-to-pack technology. Researchers have even explored using body panels as batteries, indicating a promising future for structural battery pack concepts.