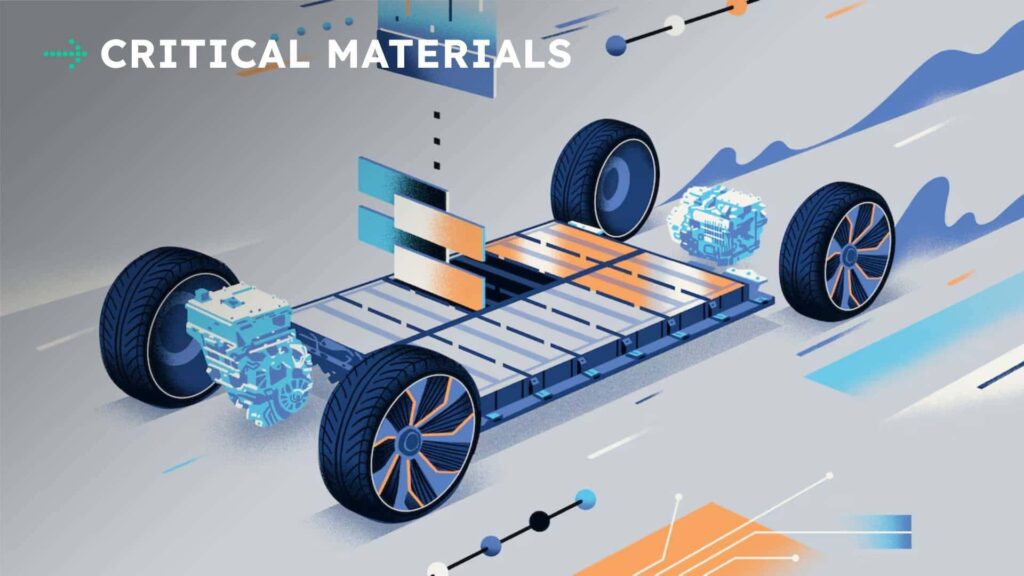

The electric vehicle industry is undergoing significant changes, with a focus on consolidation and efficiency. Automakers are working to reduce costs and maximize output by sharing platforms and embracing a circular economy approach. This approach is particularly crucial for lithium-ion batteries, the most critical component in an EV.

The concept of a circular economy involves reducing, reusing, and recycling materials instead of the traditional take, make, and dispose approach. This shift is essential for the sustainability of the EV industry and the environment. The second-life EV battery market is poised to grow significantly, potentially reaching $4.2 billion in the next decade.

Research from IDTechEx suggests that the use of nickel and cobalt in the cathode of batteries can improve energy density and make recycling more economically viable. While nickel-manganese-cobalt (NMC) batteries are more suitable for recycling, lithium-iron-phosphate (LFP) batteries present challenges due to the absence of cobalt and nickel.

The industry is expected to undergo a silent revolution in the coming years, with falling lithium prices making battery replacement in EVs even cheaper than replacing an engine in traditional cars. However, several bottlenecks need to be addressed to fully realize the potential of the second-life EV battery market.

In the U.S., the battery recycling industry is growing, with the country expected to have a recycling capacity of half a million tons annually. Repurposing EV batteries for second-life applications, such as energy storage, also presents significant opportunities.

To further advance the circular economy principles, regulations like those in China and the EU, which require minimum recycled content in batteries, may need to be implemented in the U.S. This would ensure a sustainable approach to battery manufacturing and recycling.

Meanwhile, Rivian has secured a $6.6 billion loan from the U.S. government to finance the construction of its Georgia plant. The loan is considered safe, and the plant is crucial for Rivian’s expansion plans and job creation in the region.

On the other hand, Nissan is facing challenges, with plans to offer buyouts to workers and cut shifts at its U.S. plants to save costs. The company’s merger with Honda is pending, but the road ahead may be challenging before any potential benefits materialize.

As EV batteries continue to evolve, concerns about battery health and degradation remain. However, advancements in battery technology have made EV batteries durable and long-lasting. The growing recycling ecosystem ensures that batteries are not wasted at the end of their lifespan.

Overall, the EV industry is moving towards a more sustainable and efficient future, with a focus on circular economy principles and innovation in battery technology.